The importance of edge banding

Now almost all families, in the house decoration, will be limited to consider the purchase of wooden furniture, and different brands in addition to the difference in area size, color, material, different configurations can bring intuitive different feelings of use. However, the customer's attention and understanding of the cabinet edge banding is very little. Today, let Xiaobian explain some knowledge about the cabinet edge banding.

In addition to making the cabinet more beautiful, the strict edge sealing of the furniture sheet is to better control and close the formaldehyde in the sheet. The cabinet body is closely fitted with the edge sealing strip and the sealing performance is good, which can effectively reduce the release of formaldehyde. In order to reduce processing costs, some furniture manufacturers only paste the edge on the visible front, the back and the bottom and the invisible interface do not seal the edge, so that the side without sealing the edge is easy to release formaldehyde, causing damage to human health.

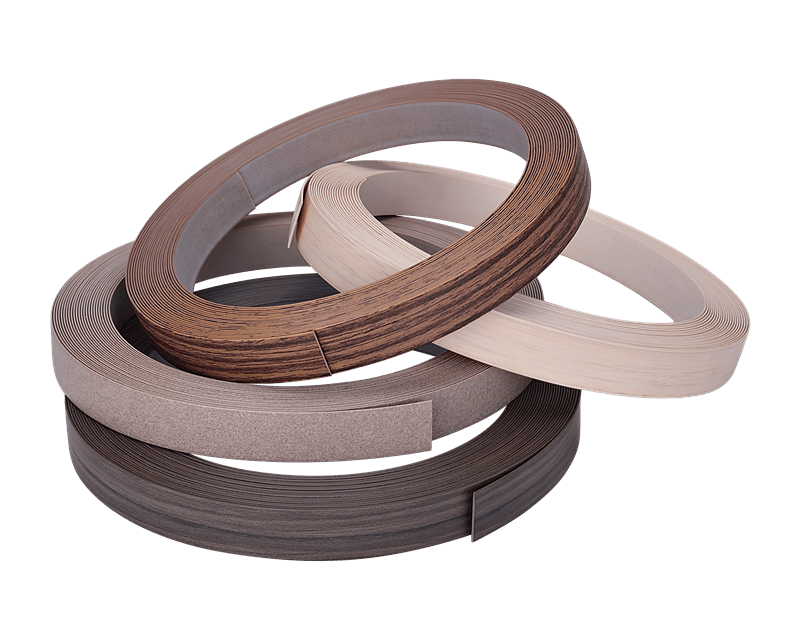

At present, there are the following kinds of edge sealing strips:

PVC (polyvinyl chloride), ABS (propylene cyanobutadiene styrene), PP (polypropylene resin), PMMA (polymethyl methacrylate), MFC melamine paper, aluminum alloy, etc. Among them, PVC and ABS are two kinds of edge sealing strips, of which ABS edge sealing effect is better, but the cost is also higher. The comparison of PVC and ABS edge banding is as follows:

1. ABS edge sealing strip does not add any filler (such as calcium carbonate and other substances) in the production process, so the rounded corners after trimming are very smooth and bright, and the surface has strong impact resistance;

PVC edge strips are slightly worse in these properties.

2, ABS edge band will shrink at a high temperature of 99 degrees; PVC at 70 degrees will have a contraction seam.

3, ABS sealing strip has a strong resistance to chemical corrosion, as time goes by, coffee, soy sauce, alcohol, etc., will not cause any damage to its surface; PVC is relatively easy to age and stain.

4, ABS sealing strip can be directly burned at high temperature without air pollution.

The edge is good or bad, you can feel it with your hand. The sealing edge of the cabinet is delicate, smooth and feels good; Poor quality edges are much rougher. In addition, some edge strips are more fragile, a break will break, and good toughness edge strips are not easy to break, but also reduce the release of formaldehyde.

The edge is a production process, which is an important factor in determining whether the furniture is environmentally friendly. The key to the quality of the production process depends on the equipment, and the edge sealing machine equipment varies from tens of thousands to millions, and some small manufacturers use manual edge sealing to save costs, which will greatly reduce the precision of the edge sealing strip, even if some brand cabinet all around the edge, but the precision of the instrument will also make the edge between the edge strip and the cabinet, resulting in formaldehyde release.

Mao-zhu edge is the domestic edge customization experts, Mao-zhu for the major furniture brands to provide a variety of edge strip series products, while adding new elements to make the edge strip appearance more fashionable, with creative patterns, textures and colors, for modern furniture design provides a new perspective, to attract the eye of furniture manufacturers and interior designers.