What is the edge banding

As we all know, the plate is composed of substrate + veneer + edge strip, and edge is a process that will seal the edge strip in a certain way on the edge of the plate, forming environmentally friendly, stable and beautiful furniture custom products.

The plate must be sealed when leaving the factory, mainly for the following two reasons:

First: Environmental protection and stability, because the base material is mixed with core material and glue, the base material contains more or less formaldehyde, and the edge can close the base material, inhibit the release of formaldehyde, but also waterproof and moisture-proof.

Second: the concealer is beautiful, the edge of the plate forms various cutting surfaces when cutting, the feel is rough, and it is easy to hide debris and bacteria, and the edge can cover all of these.

The edge strip has two kinds of material, PVC and ABS

The full name of PVC is Polyvinyl chloride, the main component of pvc edge strip is PVC, which is formed by mixing, calendering, vacuum blister and other processes. The products are widely used in furniture, office, kitchenware, teaching equipment, civil laboratory and so on. Thickness from 0.3 to 3mm, width from 12mm to 80mm. The main features of the product are: smooth surface, no foaming, no stretch, moderate gloss, flat surface and back, uniform thickness, consistent width, reasonable hardness, high elasticity, good quality, strong wear resistance.

ABS(Acrylonitrile butadiene Styrene copolymers). Unlike PVC, ABS is more environmentally friendly and can be incinerated with general waste, it is lighter in weight and highly heat-resistant. This thermoplastic material has strong impact resistance and is particularly important for office furniture. ABS has similar characteristics to PVC, but is itself more weather-resistant, so there is no need to add a stabilizer. ABS edge strip is 99% naturally recyclable and chlorine free; The advantages of lighter weight and high temperature resistance;

Most of the edge bars on the market are made of PVC material, because the edge bars of PVC material are cost-effective and stable in performance, but the edge bars of ABS material are better than the edge bars of PVC material in the same color, which means that the edge effect is more beautiful, so the price of ABS is more expensive.

In fact, not only is the material of the edge strip different, but the way of edge sealing is also divided into two kinds

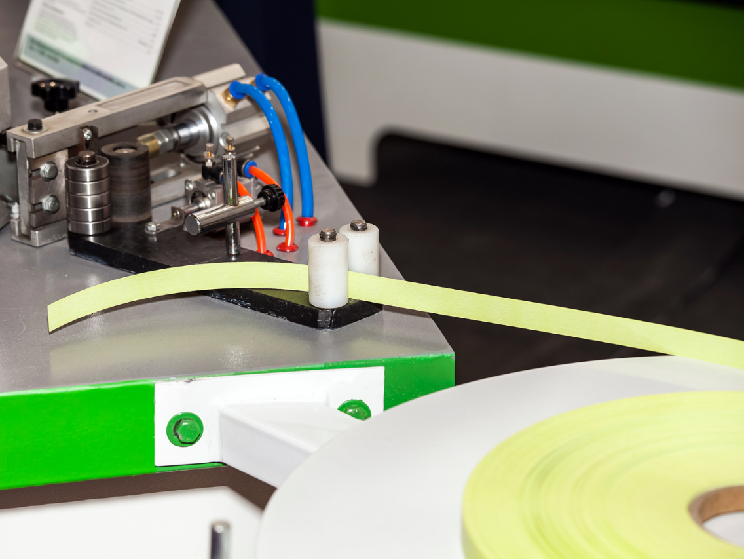

First: Edge sealing with EVA hot melt adhesive, EVA hot melt adhesive full name ethylene - vinyl acetate copolymer, is a solvent free, moisture free, 100% solid fusible polymer. It is solid at room temperature, and after melting, it is a light brown semi-transparent body or white. EVA hot melt adhesive needs to be melted at high temperature in the glue pot into a certain viscous liquid adhesive, when applied to the surface of the wood-based panel substrate or edge sealing material, cooling into a solid state, the material and the substrate bonded together. If cooling curing does not meet the requirements, it can be reheated for secondary bonding.

Second: edge sealing with PUR hot melt adhesive, PUR (Polyurethane Reactive) Chinese full name of wet curing reaction type polyurethane hot melt adhesive, heated and the air moisture irreversible reaction to cure, the plate and edge sealing strip stick together, and secondary heating will not melt.

The biggest difference between the two methods is that EVA melts when heated and PUR does not. Because EVA edge is the process of ethylene - vinyl acetate (EVA) liquefaction and recuring at high temperatures, its essence is a physical reaction. PUR edge sealing is the process of curing polyurethane resin (PUR) by reacting with water in the air at high temperatures, which is a chemical reaction in nature and is irreversible.

The vast majority of the market is EVA edge, PUR belongs to the emerging process. In fact, the specific effect of the glue line depends on the construction specifications, the use of glue, the trimming situation, etc., and you need to go to the business or the manufacturer to compare the real sample.

For the choice of edge sealing method, most businesses mainly consider the budget factor for the cabinet: Relatively speaking, EVA edge sealing is more affordable than PUR edge sealing. As for the quality performance and the degree of environmental protection considerations, EVA edge is easy to crack at high temperature, and the conventional sealing quality is guaranteed, the main influencing factor of environmental protection is the glue content of the substrate, and the glue of the plain board veneer.

The above is a brief introduction to the edge sealing material and the edge sealing method.