Products

New Products

Top Grade Pure ABS Countertop Edging for Kitchen Cabinet Decoration

Top Grade Pure ABS Countertop Edging for Kitchen Cabinet Decoration Fabric pattern cabinet PVC side tape

Fabric pattern cabinet PVC side tape Extremely flexible 2mm self-adhesive plastic pvc edge banding

Extremely flexible 2mm self-adhesive plastic pvc edge banding Wide wood grain trim Wood finish ABS edge band

Wide wood grain trim Wood finish ABS edge band Furniture Edge Lipping Skin Feel Pvc Edge Sealing Tape

Furniture Edge Lipping Skin Feel Pvc Edge Sealing Tape The new stone color 99% matches the pvc edge band of the veneer

The new stone color 99% matches the pvc edge band of the veneer- All products

ABS edge band for children's furniture

ABS edge band for children's furniture is usually made of environmentally friendly materials that do not contain harmful substances and meet the safety standards for children's furniture. The material itself is impact-resistant, which can mitigate the potential harm to children from bumping furniture edges. The surface of ABS edge band for children's furniture is usually smooth and easy to clean. This is especially important for children's furniture, which is susceptible to food, liquid and other stains. It is usually made of environmentally friendly materials and meets the environmental standards for children's products to ensure children's health and safety.

Send Inquiry

Product Description

ABS edge band for children's furniture

ABS edge band for children's furniture is usually made of environmentally friendly materials that do not contain harmful substances and meet the safety standards for children's furniture. The material itself is impact-resistant, which can mitigate the potential harm to children from bumping furniture edges. The surface of ABS edge band for children's furniture is usually smooth and easy to clean. This is especially important for children's furniture, which is susceptible to food, liquid and other stains. It is usually made of environmentally friendly materials and meets the environmental standards for children's products to ensure children's health and safety.

1.Product Properties

|

Model |

ABS |

|

|

Type |

Edge banding |

|

|

Product name |

ABS edge band for children's furniture |

|

|

Materials |

Acrylonitrile |

|

|

Thickness |

Thickness 0.4mm to 3mm |

Customizable size |

|

Breadth |

Width 6mm to 90mm |

Customizable size |

|

Inner ring |

The inner ring length can be customized |

|

|

Colour |

Custom (provide sample color according to customer) |

Exploitable design |

|

Business type |

Make |

|

|

OEM/ODM |

Accept customization |

|

|

Sample |

0 cents /20cm sample available |

|

|

Minimum order quantity |

6000 m |

|

|

Brand |

MJUNE |

|

2.ABS edge band for children's furniture product features

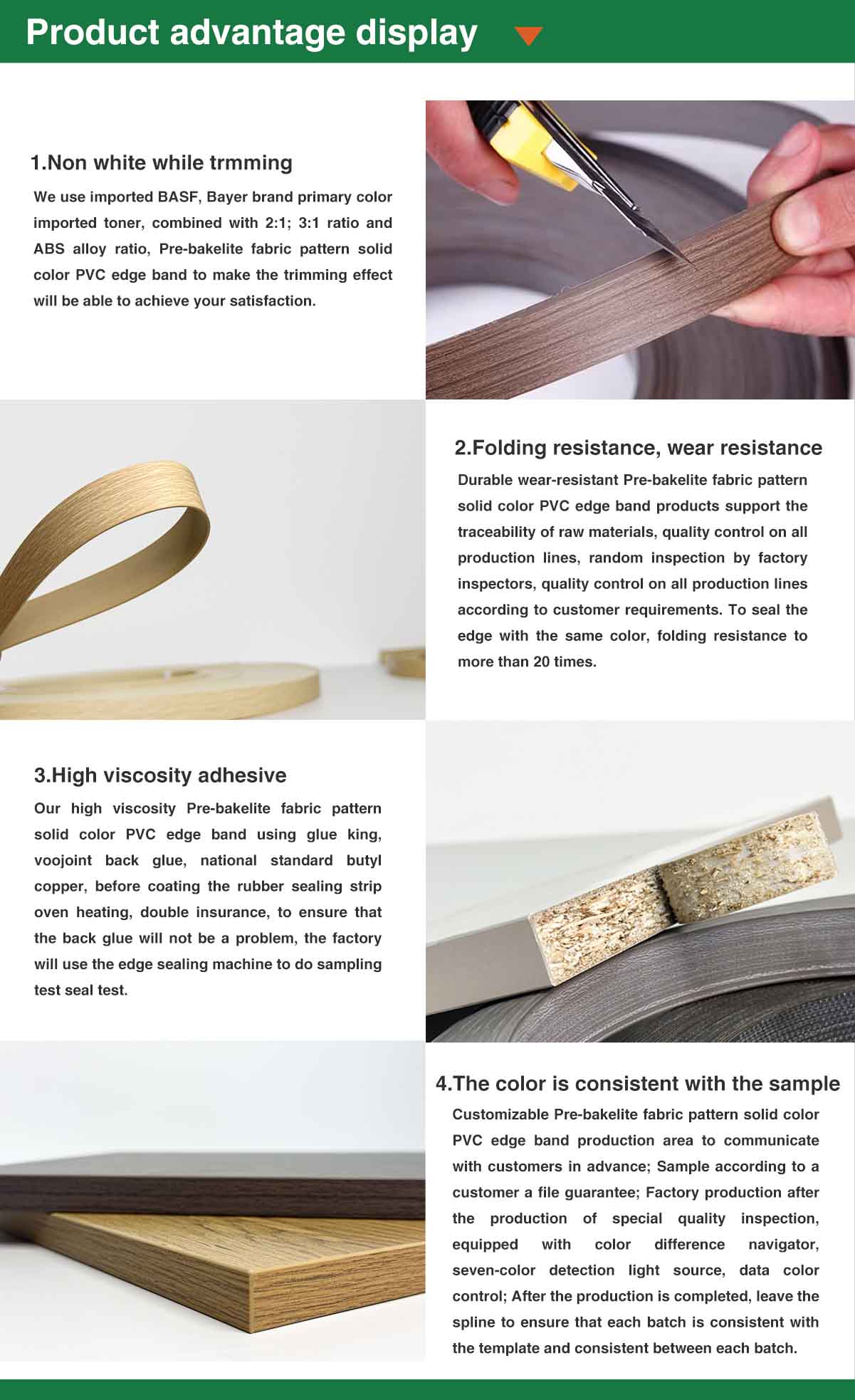

1.Non white while trmming

We use imported BASF, Bayer brand primary color imported toner, imported BASF and Bayer brands are usually known for their high quality raw materials. The selection of primary imported toners from these brands helps ensure color stability and accuracy, combined with 2:1; 3:1 ratio and ABS alloy ratio, the ABS edge band for children's furniture has certain safety, durability and easy cleaning, and the trimming effect can also meet customer expectations and improve customer satisfaction.

2.Folding resistance, wear resistance

Durable ABS edge band for children's furniture products support the traceability of raw materials, quality control on all production lines, random inspection by factory inspectors, to achieve the effect of edge sealing and trimming with the same color, and also has a certain elasticity and bending resistance.

3.High viscosity adhesive

Our high viscosityABS edge band for children's furniture using glue king, voojoint back glue, national standard butyl copper, Before applying the back glue, it will also be heated in the oven to achieve solid quality, and before leaving the factory, it will also use the edge sealing machine to do sampling test sealing test for secondary reinforcement.

4.The color is consistent with the sample

Customizable ABS edge band for children's furniture production area to communicate with customers in advance;Retained sample to achieve a customer a file retention; The factory also has a special quality inspector and equipped with color difference navigator and seven-color detection light source for data color control; After the production is completed, leave the spline to ensure that each batch is consistent with the template and consistent between each batch.

3.To enhance quality and compliance, our PVC edge banding products have been awarded ISO 9001 certification and SGS certification.

ISO 9001 Quality Management System Certification: ISO 9001 is the most widely used international standard for quality management systems and requires us to establish and maintain an effective quality management system to ensure that our products and services continue to meet our customers' expectations. This certification demonstrates that they not only have a high quality management system in place, but that they also monitor and improve processes to ensure consistency and excellence in products and services, as well as our commitment to continuous improvement.

SGS Certification: SGS is an international company with wide international recognition. Its certification and validation are generally recognized by governments and industry organizations, so verification by SGS helps to gain greater trust and recognition in the global market.

4.Packing and delivery

|

Packaging type |

Standard carton, suitable for long distance transportation, the outer box is bound by PP strips. Each 20-foot container can hold about 700 cartons. We can manufacture according to your needs, such as printing your company logo on a carton, website. |

Detailed packing details are required |

|

package |

50 m /100 m /200 m /300 m roll |

|

|

Delivery time |

2-30 weeks after receiving the 30% advance payment |

|

|

Payment method |

Wire transfer, Letter of Credit, Pay Pal, Western Union |

|

5.Supply capacity

|

Supply capacity |

200,000 meters/day supply |

6.Transport

|

Type of transportation |

Ship by sea, air or courier. |

7.Our advantage

1.The company has its own professional R & D team, and provides OEM and ODM customization services for children's furniture ABS edge tape, while carrying out 100% QC inspection in the production process to ensure product quality. In addition, the sales team can also provide professional reference suggestions and solutions to help customers solve pre-sales and after-sales problems.

2.Our environment-friendly ABS edge band for children's furniture is currently using national standard CPE, lead-free stabilizer, p-benzene, DOTP and other raw materials. Has passed SGS testing, the product does not contain lead, no heavy metals, no 16P (phthalates).

3.At present, the factory is equipped with brand LOGO”MJUNE” invisible anti-counterfeiting, in the production process, to ensure brand quality self-inspection and self-inspection at the same time also has a high degree of identification and anti-counterfeiting, so that customers are more comfortable and secure.

4.At present, the factory is equipped with more than 200 steel matching pattern embossed wheels, and more than 500 matching pattern roller with wood grain,It can also open a special edition to provide customers with a variety of customized services, and can achieve more than 95% of the degree of customization.

FAQ

Q1: Are you a manufacturer or a trading company?

A1: We are professional edge edging band manufacturer. We have a newly built factory, the size of which is in the top 10 in the field. We focus on producing edging products rather than just trading them. You are welcome to visit our factory to better understand our production capacity and product quality.

Q2: Can I have a sample order for PVCABS banding?

A2: Yes, we welcome small sample orders so that you can evaluate the quality of our products and their suitability for your project.

Q3: What is the production cycle?

A3: Once we receive the deposit, we can usually complete the order in 15 to 20 days. Please note that the exact delivery time may vary depending on the number of orders and your location, and you can negotiate specific delivery schedules with our sales team.

Q4: What is the minimum order quantity?

A4: For the colors in our stock, the MOQ is 6000 meters per color. If you need to customize the color, the minimum order quantity is 10,000 meters per color. Please contact our sales team for more details on MOQ and color customization.

Q5: Can I print my logo on the carton?

A5: Yes, we can provide custom packaging services, including printing your logo or logo on the carton. This will help make your product more branded. Please discuss your custom packaging needs further with our sales team.

Q6: Do you charge samples and shipping?

A6: We provide free samples, but the customer needs to pay the shipping cost of the samples. Once you place your first official order, we will refund the cost of the sample.

Q7:What is the thickness of PVC, ABS edge sealing strip?

A7: Our PVC, ABS edge strip thickness can be customized: 0.45-3 mm. Width can be customized: 13-80 mm. We can also make according to the special needs of customers, if you have special requirements, please feel free to tell us.

If you have any additional questions or need further information, do not hesitate to contact our sales team at any time. We are happy to support you and answer all your questions.