What is the difference between PVC and ABS edging?

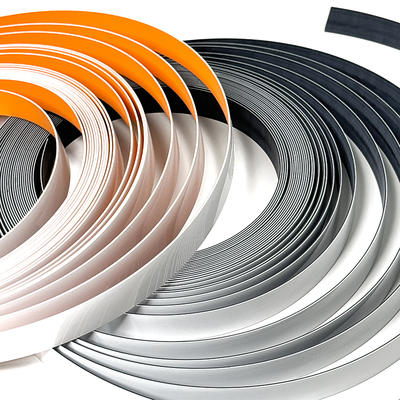

In the world of materials science, PVC and ABS are two of the most widely used plastics. However, while they may seem similar at first glance, there are distinct differences between PVC and ABS edging that are crucial for understanding their unique properties and applications.

PVC, or polyvinyl chloride, is a tough, durable, and highly versatile material. It is commonly used in a wide range of applications, including piping, flooring, and window frames. PVC edging is often chosen for its resistance to wear and tear, as well as its ability to withstand harsh environments and temperatures. It is also relatively inexpensive, making it an attractive choice for many budget-conscious consumers.

On the other hand, ABS, or acrylonitrile butadiene styrene, is a more heat-resistant plastic that offers better mechanical properties compared to PVC. ABS edging is often chosen for its improved impact resistance and greater tolerance for hot and cold temperatures. It is commonly used in automotive and electronic applications due to its superior performance under extreme conditions.

Another key difference between PVC and ABS edging is their chemical resistance. While PVC is highly resistant to most chemicals, ABS offers superior resistance to solvents and certain acids. This makes ABS edging a better choice for environments that require exposure to harsh chemicals or solvents.

In terms of sustainability, both PVC and ABS edging have their environmental impacts. PVC can be difficult to recycle due to its stability under normal recycling conditions. On the other hand, ABS is easier to recycle and is often considered more environmentally friendly than PVC due to its lower carbon footprint during production.

In conclusion, the choice between PVC and ABS edging depends largely on the specific requirements of the application. PVC offers excellent durability and versatility at a lower cost, making it suitable for many indoor and outdoor applications. ABS, on the other hand, offers superior mechanical properties, chemical resistance, and ease of recycling, making it a better choice for extreme environments or applications that require exposure to harsh chemicals. Understanding the unique properties of each material is crucial for selecting the most suitable edging for a given project.