How to distinguish PVC edge banding and ABS edge banding

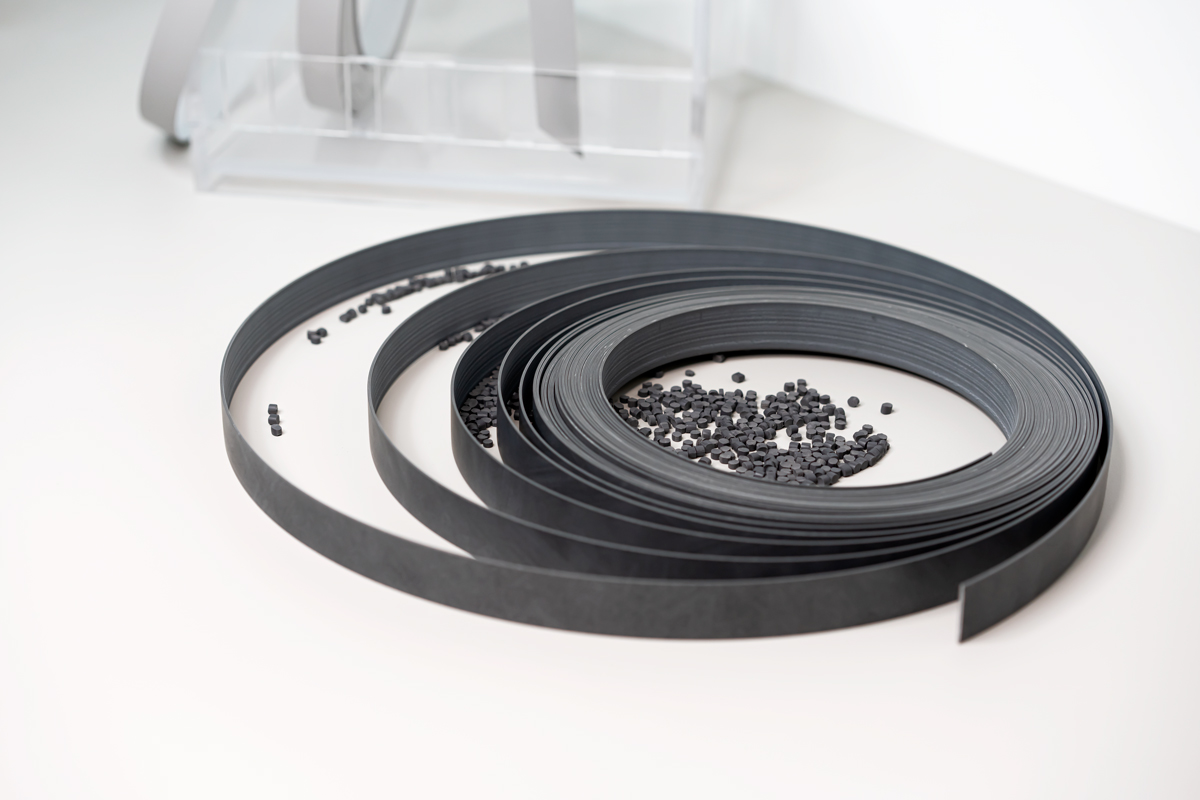

As we all know, the edge sealing strip is roughly divided into two types of PVC and ABS according to different materials.

PVC is a kind of plastic decoration material, is the abbreviation of polyvinyl chloride thin material, is based on polyvinyl chloride resin as the main raw material, its acid and alkali resistance is better, chemical stability is better, but the softening point is low, suitable for the production of thin sheet, wire and cable insulation layer, seals and so on. PVC material is light, heat insulation, moisture, flame retardant, construction for the interior wall and ceiling decoration, is one of the most widely used decorative materials

The advantages of PVC are mainly reflected in:

1, light weight, heat insulation, heat preservation, moisture, flame retardant, acid and alkali resistance, corrosion resistance.

2, stability, good dielectric, durable, anti-aging easy to weld and bond

3, strong bending strength and impact toughness, high elongation when broken.

4, through kneading, mixing, drawing, cutting, extrusion or casting process is easy to process molding, can meet the needs of various profile specifications

The molding characteristics of PVC are:

1, amorphous material, medium fluidity, large moisture absorption, must be fully dry, the surface requirements of the glossy plastic parts must be preheated and dried for a long time, 80~ 90 degrees, 3 hours

2, easy to decompose, at 200 temperature with steel, copper contact is more easy to decompose, forming temperature range is small

The advantages of ABS are:

- Good environmental protection and strong degradability.

2, good overall performance, high impact strength, chemical stability, good electrical performance

The forming characteristics of ABS are:

1, light weight, heat insulation, heat preservation, moisture, flame retardant, acid and alkali resistance, corrosion resistance.

2, suitable for high material temperature, high mold temperature, but the material this high decomposition (temperature is 7270 degrees) for high precision plastic parts, mold temperature is suitable for 50-60 degrees, for high gloss, heat-resistant plastic parts, mold temperature is suitable for 60-80 degrees.

3, its color is opaque, light ivory, non-toxic, tasteless, both tough, tough characteristics, slow burning.

The contrast between ABS and PVC products is reflected in:

1.ABS edge sealing does not add any fillers such as calcium carbonate in the production process, so the rounded corners after trimming are very smooth and beautiful, and the surface has strong impact resistance. Due to the addition of calcium carbonate filler, PVC is prone to white edges when trimming

2, ABS will shrink at a high temperature of 99 degrees, while PVC will shrink at 70 degrees, resulting in sheet deformation and expansion

3. ABS has strong corrosion resistance to chemical substances

4, ABS is non-irritating, PVC has a plastic taste

5, ABS can be directly burned at high temperature without atmospheric pollution, PVC will produce dioxin gas, which may cause greenhouse effect.

Although PVC and ABS are different materials, they are both plastic preparations, so the products produced with them also belong to plastic products from a large range of points of view, the difference is not very obvious. Practitioners are naturally easy to distinguish, but consumers are not so good to identify, so some bad businesses take advantage of the vulnerabilities that consumers do not know much about edge banding, and use relatively cheap PVC edge banding strips to pretend to be more expensive ABS edge banding strips to fool consumers. Here are a few simple ways to distinguish.

1, weight: PVC edge strip and ABS edge strip is the easiest way to distinguish the weight, ABS raw material weight is much lighter than PVC.

2, texture: due to different production materials, ABS edge strips feel more delicate, basically will not appear rough edge and other bad touch.

3, smell: open fire ignited edge strip, relative to ABS edge strip PVC edge strip smell to pungent.

4, flexibility: This is the most direct way to determine whether ABS or PVC edge banding, ABS edge banding because of its environmental protection and easy degradation characteristics, so it must sacrifice its flexibility, so ABS edge banding is easier to break. The PVC edge strip is more tough.

The above is a simple science popularization for the difference between PVC edge banding and ABS edge banding.